Measuring the Thickness of Lithium Battery Electrodes Using High-Precision Laser Displacement Sensors

High-Precision Laser Displacement Sensors for Accurate Thickness Measurement of Lithium Battery Electrodes

Principle of Operation for Laser Displacement Sensor

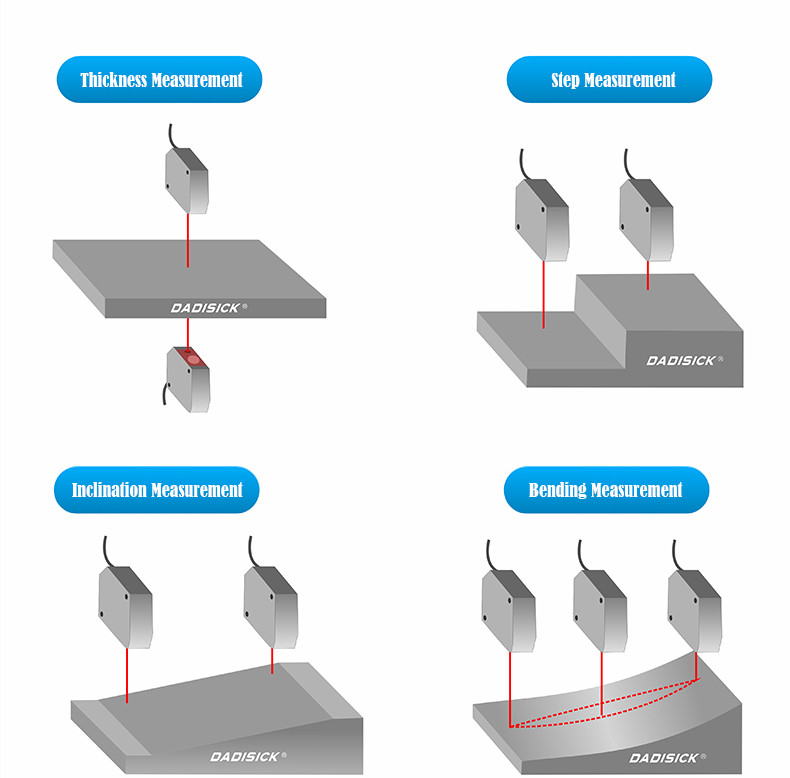

Method of Measurement for Laser Displacement Sensors

Thickness Measurement:

First, fix the laser displacement sensor on the test bench and adjust the distance between the sensor and the measured electrode to ensure that the laser beam can correctly hit the surface of the electrode. Then, operate the control system to scan the electrode with the laser displacement sensor and record the displacement data of each point. By processing and analyzing the displacement data, the thickness distribution of the electrode can be determined.Accuracy Calibration:

To ensure measurement accuracy, the laser displacement sensor needs to be periodically calibrated. Generally, standard reference blocks can be used for calibration. Place the standard reference block on the test bench and adjust the position relationship between the laser displacement sensor and the reference block so that the laser beam can vertically hit the surface of the reference block. Then, operate the control system to scan the reference block with the laser displacement sensor and record the displacement data. By analyzing and processing these data, the accuracy error of the sensor can be determined and corresponding adjustments and compensations can be made.Stability Check:

To ensure the reliability of measurement results, the stability of the laser displacement sensor needs to be periodically checked. Generally, long-term monitoring can be used for stability checks. Place the laser displacement sensor on the test bench to scan a fixed measured object and record the measurement data over a period. By analyzing and processing these data, the stability error of the sensor can be determined and corresponding adjustments and compensations can be made.Advantages of Using Laser Displacement Sensors for Measurement

Recommended Laser Displacement Sensors

|

Sensing Distance

|

Repeatability

|

Linearity |

Output

|

|

30 mm (±5)

|

10 µm

|

±0.1%F.S. |

Analog / RS485

|

|

50 mm (±15)

|

30 µm

|

NPN / Analog / RS485

|

|

|

100 mm (±35)

|

70 µm

|

||

200 mm (±80) | 200 µm | ±0.2%F.S. | |

400 mm (±200) | 400 µm / 800 µm | ||

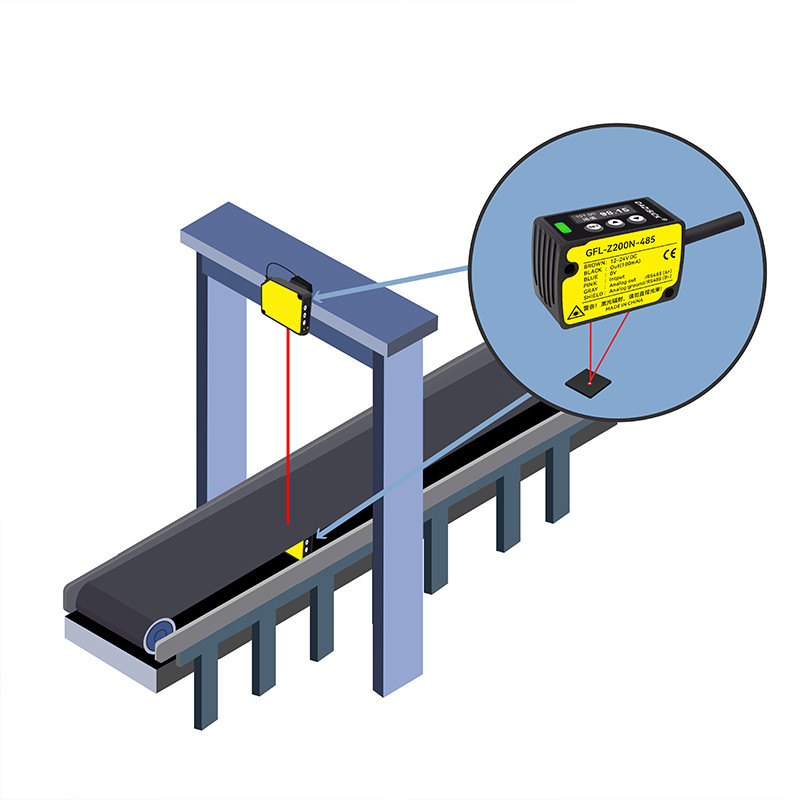

Applications of Laser Displacement Sensors | |||

Laser displacement sensors are versatile measurement tools capable of accurately measuring physical quantities such as length, distance, vibration, speed, and angle. Laser displacement sensors play a crucial role in applications such as small part identification, conveyor belt monitoring, material overlap detection, robotic position control, liquid level monitoring, thickness measurement, vibration analysis, collision testing, and various automotive tests. | |||